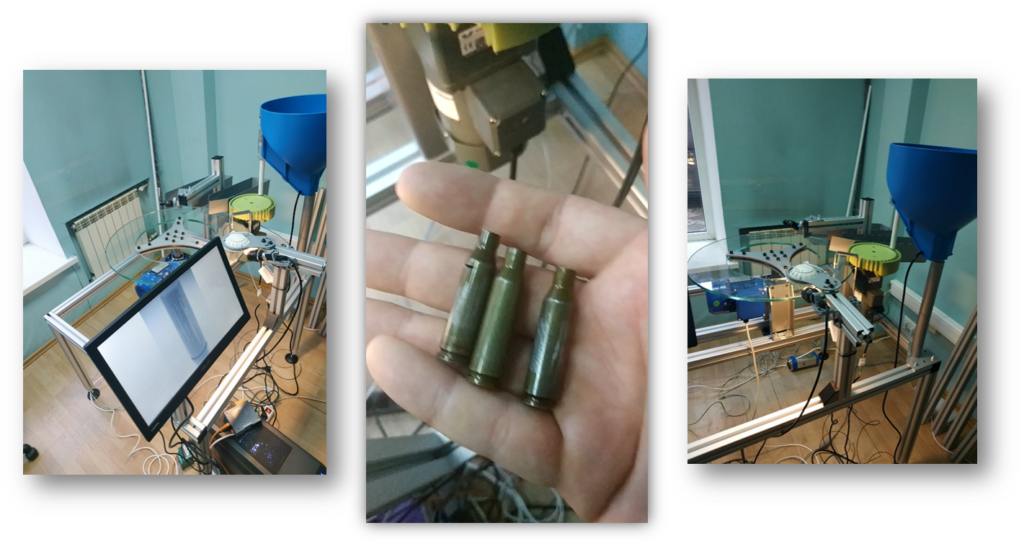

Cartridge case defect inspection system

The cartridge case defect inspection system (CC-DIS) is designed to detect and reject cartridge case defects.

CC-DIS is a hardware and software package from the feeder (cartridge case loading) to the glass rotary table that is used to position cartridge cases in the inspection area and then move and sort them into failed and passed products.

Minimum defect size = 0.5 mm.

The duration of one CC-DIS inspection cycle is not more than 0.3 second.

The CC-DIS frame consists of structural aluminum shapes. Downstream the feeder, a special-shaped feed wheel is installed to position appropriately cartridge cases in the field of view of machine vision cameras.

Write to us