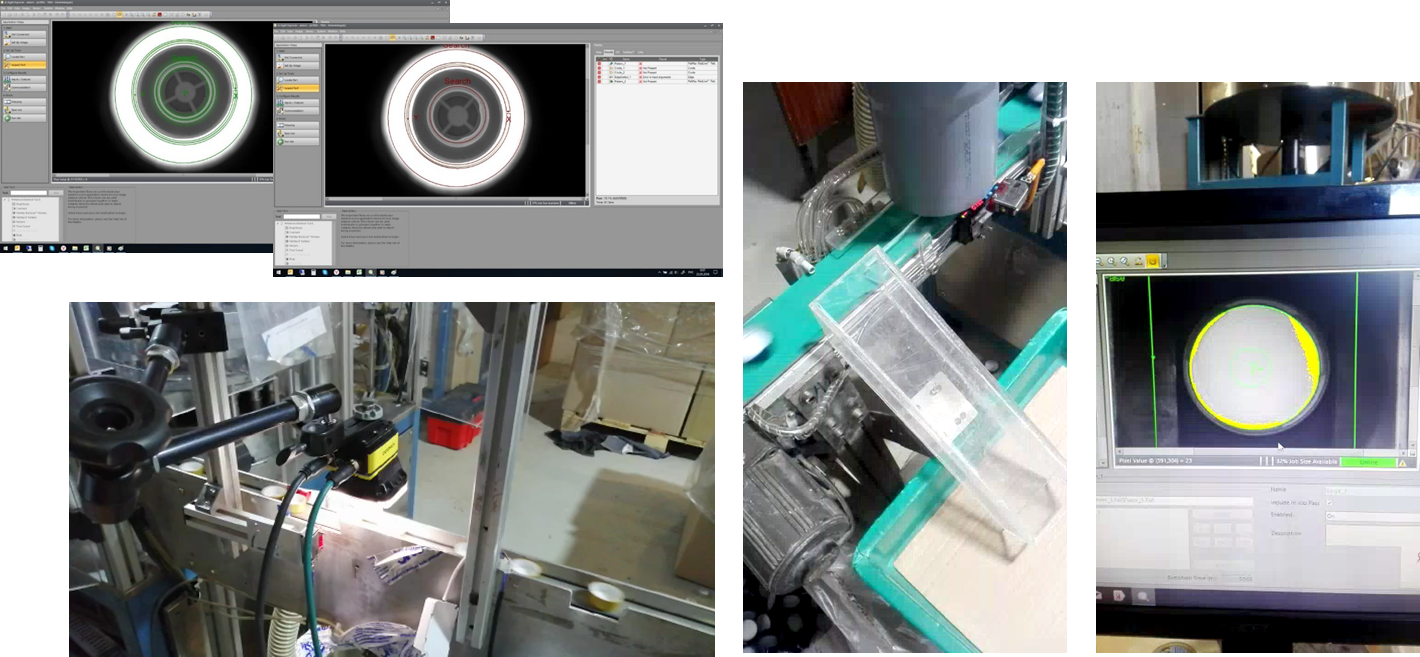

Vodka and cognac cap defect inspection system

The vodka and cognac cap defect inspection system (VCC-DIS) is designed to detect make and assembly defects of plastic and metal caps for vodka and cognac products.

Minimum defect size = 0.5 mm.

Common defects: scores, creases, burrs, cracks, scratches, foreign particles, missing membrane, missing plastic insert, glue traces, etc.

VCC-DIS inspection cycle productivity: 7 caps per second.

When a defect is detected, the VCC-DIS generates a digital reject signal.

The VCC-DIS is equipped with flexible software to adjust the sensitivity limits of rejection criteria and add new cap types to be inspected.

Write to us