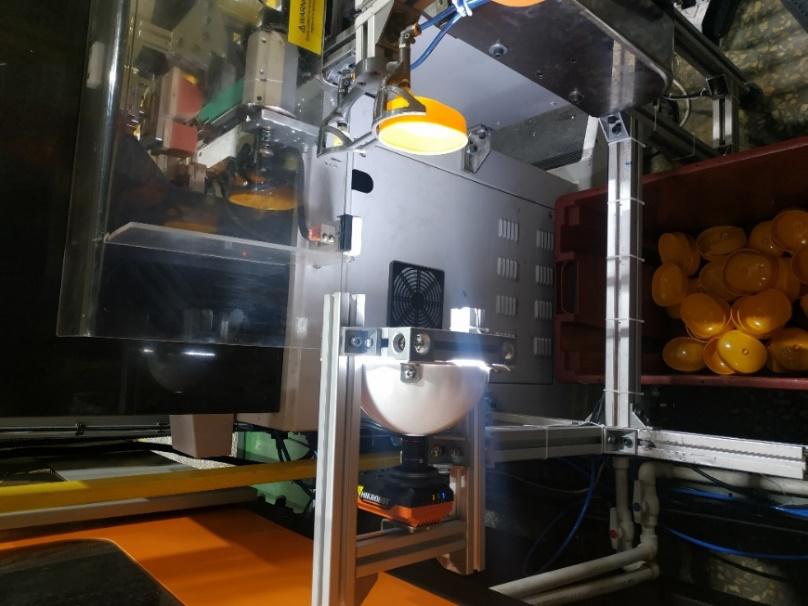

Underfill inspection* system

The casting inspection system (hereinafter referred to as CIS) is designed to detect casting defects in plastic products (overfill and underfill).

Minimum defect size = 2.0 mm.

The duration of one CIS inspection cycle = not more than 1.0 seconds.

To inspect casting, the robot alternately positions plastic products in the field of view of the machine vision camera.

If no defect is detected, the robot moves the plastic products by conveyor to the printing area.

If the defect is detected, the robot's vacuum cups are switched off and the defective plastic products are moved by gravity into the scrap container.

To enable prompt viewing of print inspection results, a graphical operator interface has been developed.

If the defect is detected, the operator panel displays NG on a red background. If no defect is detected, OK is displayed on a green background.